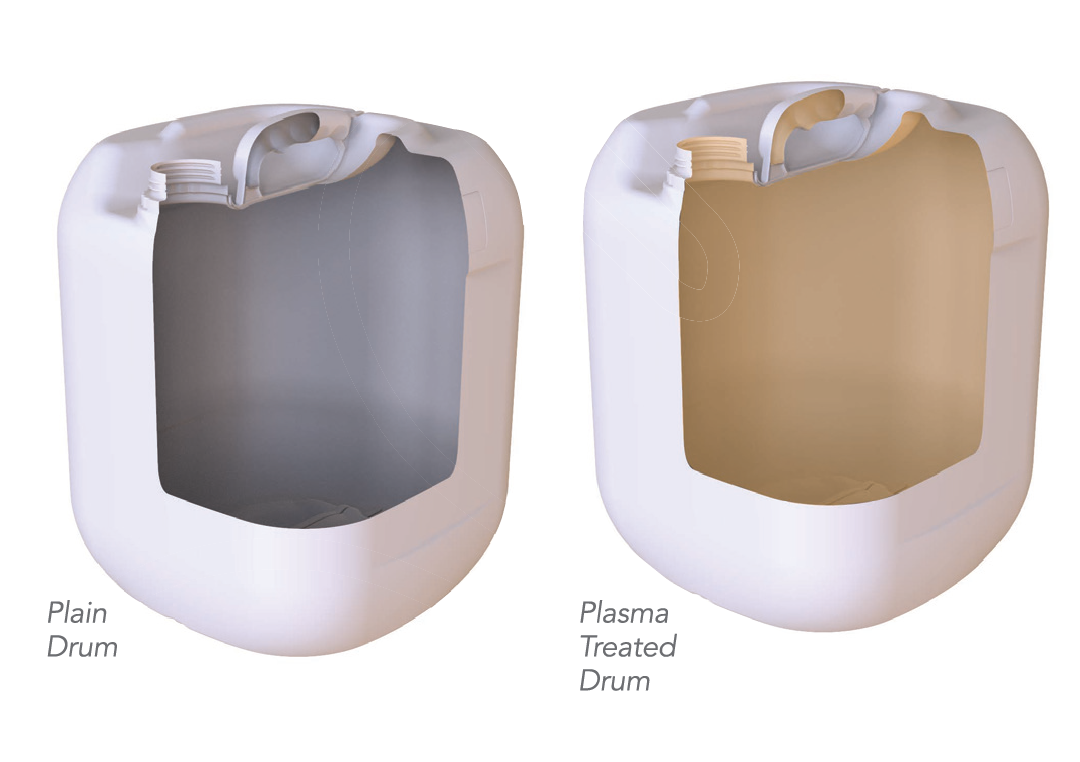

High Density Polyethylene (HDPE) is commonly used in rigid plastic packaging as it is durable, lightweight, recyclable and reusable. Its molecular structure is relatively porous though, enabling certain hydrocarbon solvents to permeate through the packaging walls, resulting in evaporation of contents and deterioration of the mechanical properties of the packaging, seen as panelling.

Permeation can be prevented by introducing a barrier layer to the packaging walls, to change the surface characteristics of the polymer. The traditional method of achieving this has been through Fluorination. However, fluorine gas is today considered dangerous which is why many European countries have moved way from this technology.

Blowpack now offers its customers the more superior barrier technology in the form of Plasma Coating which is as effective but much safer. Permeation tests conducted through a certified UN testing laboratory confirms that the barrier formed on the wall of the packaging is equivalent to that of fluorinated packaging, and and in terms of UN permeation it passed the toxic level threshold.

Talk to us for your barrier protection requirements!